PLC controlled High Line Sizing Machine with multi-point drive. Perfect control of size pick-up, stretch and hairiness.

Main Features :

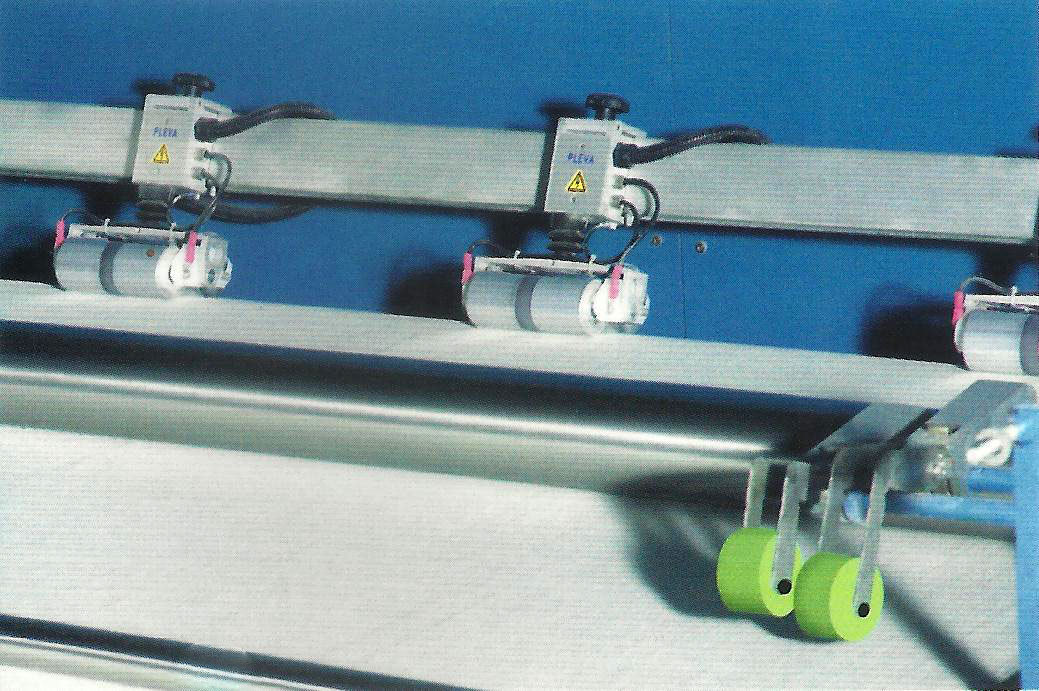

- Optimum and uniform size pick-up

- Minimum loss in elongation

- Minimum hairiness

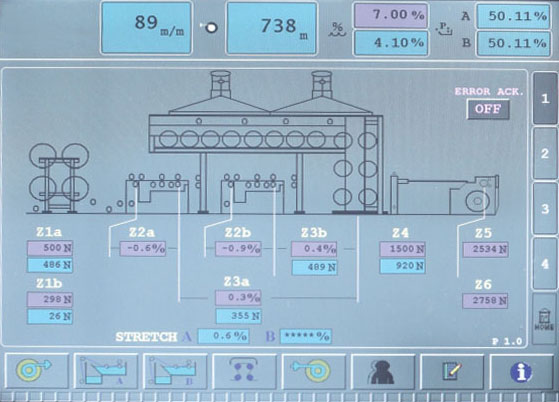

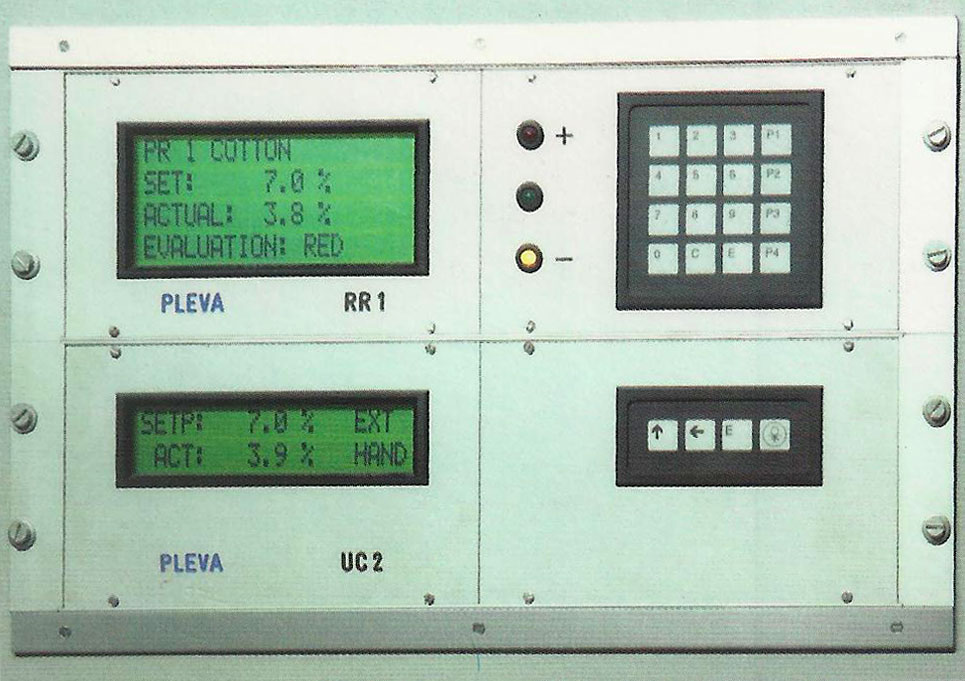

- Automatic tension control in different zones through PLC (Programmable Logic Control

- Automatic control of different parameters such as temperature in size box / cylinder, squeezing pressure, beam pressure & pneumatic brake at creel

- Higher production with good quality

- User friendly HMI (Human Machine Interface)