Multi Point PLC Based low Line Sizing machine

LOW LINE SIZING MACHINE HAS BEEN SPECIALLY DEVELOPED TO MEET THE REQUIREMENT OF THOSE CLIENTS WHO WANT TO SIZE DIFFERENT COUNTS TO FEED 100 RPM TO 1000 RPM AIRJET LOOMS WHICH IS NOT POSSIBLE IN HIGH LINE SIZING MACHINE.

WE HAVE DESIGNED IT WITH CONVENTIONAL MECHANISM & ADDED IT WITH LATEST ELECTRONIC GADJETS WHICH WE USE IN OUR HIGH LINE SIZING MACHINE TO REDUCE THE COST & GIVE THE BEST PERFORMANCE ON HIGH RPM LOOMS.

- Heavy duty Head Stock with main motor (10-20HP) for drive to drag roll, cylinder & size box & Winder Motor (15-30 HP) for Beam Drive

- Working width (mm) : 1800 to 4000

- Flange diameter (mm) : 600 to 1250

- Beam pressing device (pairs of roll) : Pneumatic floor mounted

- Doffing / Donning : with Servo Drive

- Individual lenze german make geared motor & servo drive.

- MOISTURE CONTROLLAR = PLEVA (GERMANY).

- Proportionate Squeezing.

- TEMPRATURE CONTROLLAR THROUGH PID VALVE.

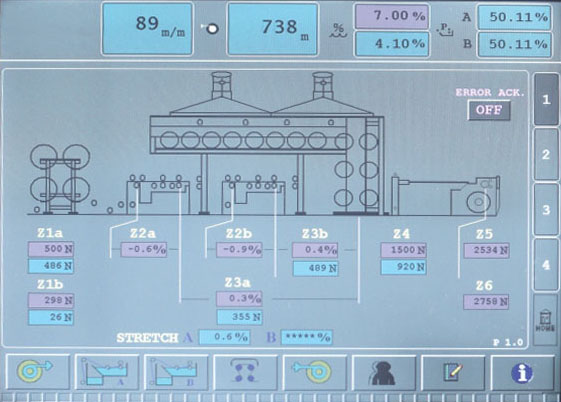

- AUTO STRETCH CONTROL.

- AUTO SIZE LEVAL CONTROL.

- WITH HUMAN MACHINE INTERFACE (HMI)

- INBUILT DATA STORAGE