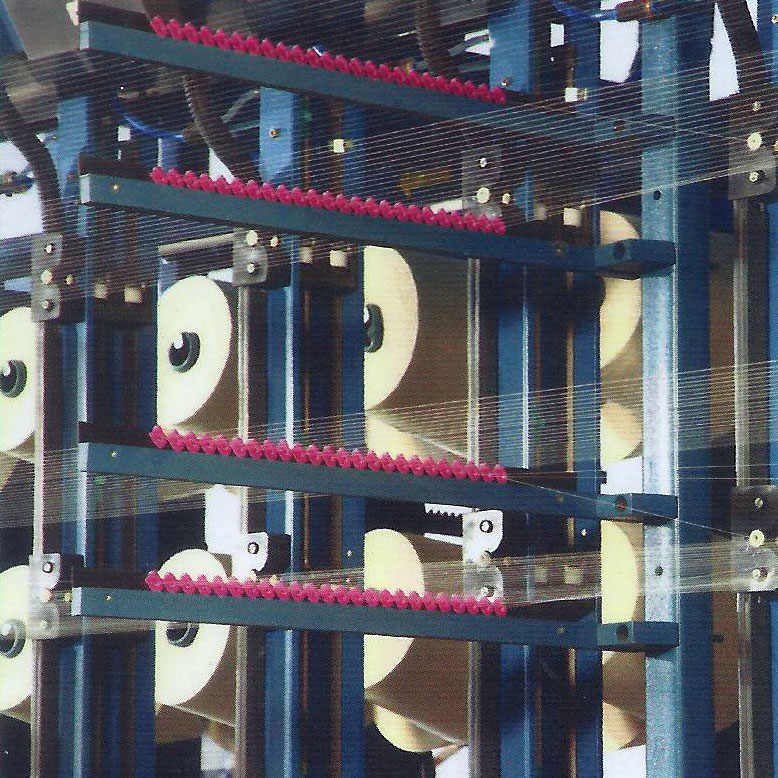

| PITCH DISTANCE HORIZONTAL & VERTICAL | 270MM | 280MM | 320MM | 360MM | 360MM | 400MM | 450MM |

| NO. OF ROWS | 8 | 7 | 6 | 5 | 6 | 5 | 5 |

| NO. OF PEGS IN EACH TROLLY/MODULE | 96 | 84 | 60 | 40 | 48 | 40 | 30 |

| RANGE OF ENDS | 96-864 | 84-756 | 60-660 | 40-520 | 48-720 | 40-440 | 30-480 |

| CREEL HEIGHT | 2790MM | 2560MM | 2560MM | 2560MM | 2760MM | 2600MM | 2930MM |

| HEIGHT OF TOP TIER FROM FLOOR | 2190MM | 1960MM | 1960MM | 1960MM | 2160MM | 2000MM | 2221MM |

| HEIGHT OF BOTTOM TIER FROM FLOOR | 300MM | 280MM | 360MM | 360MM | 360MM | 400MM | 421MM |

| MODULE LENGHT | 1620MM | 1680MM | 1600MM | 1440MM | 1440MM | 1600MM | 1350MM |